Diaphragm seal pressure and differential pressure transmitters are typically customized products. By integrating standard transmitter bodies with customized diaphragm seal assemblies and applying complete vacuum evacuation, oil filling, temperature compensation, and calibration processes, measurement performance equivalent to factory-assembled diaphragm seal transmitters can be achieved, meeting the requirements of a wide range of industrial applications.

When purchasing flange-mounted pressure transmitters or diaphragm seal differential pressure transmitters, have you ever noticed this phenomenon:

Why do most distributors often offer lower prices than the original manufacturer, along with significantly shorter delivery times?

This is not a coincidence, but a long-standing common practice in the pressure transmitter industry.

In actual inventory planning, almost all suppliers prioritize stocking threaded pressure or differential pressure transmitters, while rarely keeping flange-mounted or remote diaphragm seal types in advance. The reason is that parameters such as flange standards, diaphragm materials, filling fluids, and capillary lengths are highly customized. Stocking these configurations in advance not only incurs high costs but also carries substantial inventory risks.

When customers request flange-mounted pressure transmitters or diaphragm seal pressure transmitters measurement solutions, suppliers typically take an existing transmitter body and send it to a specialized diaphragm seal assembly manufacturer, where customization is carried out according to the specific process conditions. The complete process includes:

Design and assembly of the diaphragm seal and/or capillary system

System evacuation and precision oil filling

Temperature compensation and long-term stability treatment

Factory calibration and performance verification

After these procedures, the transmitter can achieve measurement accuracy, response characteristics, and field applicability equivalent to original factory diaphragm seal products, and is widely used across various industrial applications.

This is exactly the service we provide: customized diaphragm seals system.

We specialize in delivering customized diaphragm seal components and flange-mounted remote seal solutions for pressure and differential pressure transmitters. While ensuring measurement performance and reliability, we help customers gain more flexible lead times, more competitive cost structures, and product configurations that are better aligned with real operating conditions.

01. Flange Manufacturing

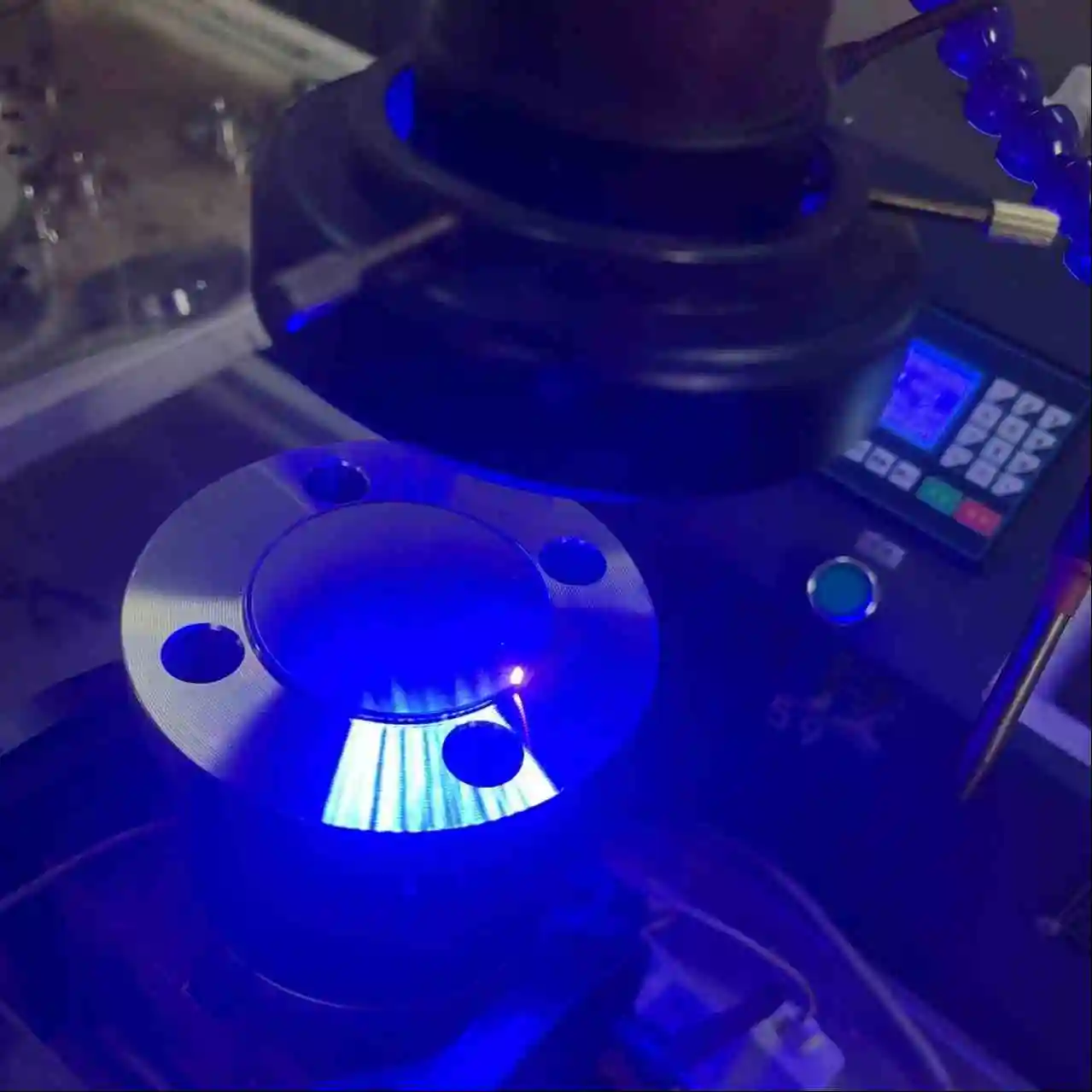

02. Diaphragm Welding

03. Vacuum leak detection

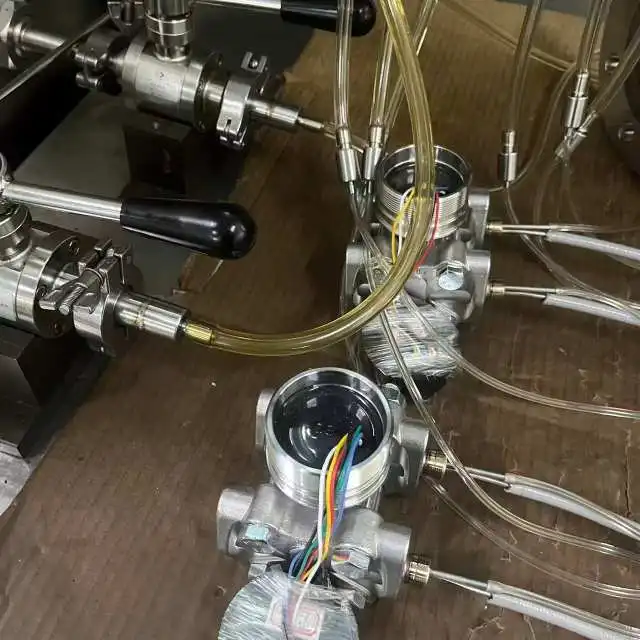

04. Capillary Tube Welding

05. Secondary Leak Inspection

06. Vacuum Evacuation

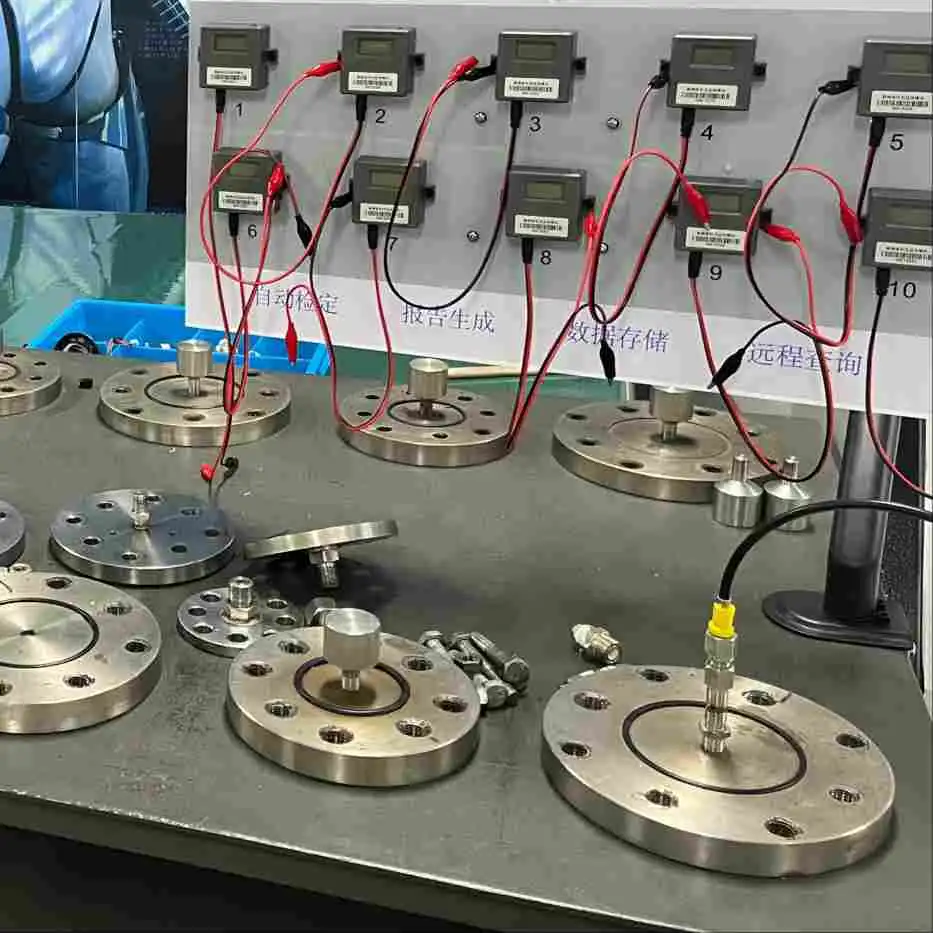

11. Final Pressure Calibration

10. Temperature Compensation

09. Pressure Testing

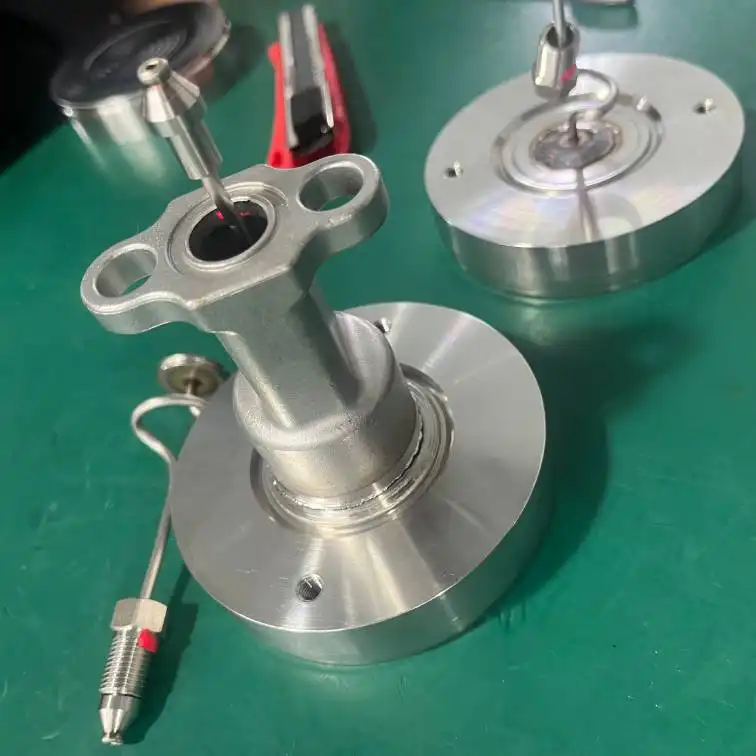

08. Assemble Diaphragm Seal Part

07. Capillary Oil Filling

Custom-built diaphragm seal transmitter configurations for pressure and differential pressure measurement applications.

These photos showcase a selection of diaphragm seal customized projects and diaphragm seal pressure transmitter assemblies completed in 2025.

Each unit is manufactured based on specific process conditions, including flange standards, diaphragm materials, filling fluids, capillary configurations, and calibration requirements.

From single flange-mounted diaphragm seals to remote diaphragm seal systems with capillary tubing, all products are assembled, oil-filled, temperature compensated, and pressure calibrated to ensure reliable performance in real industrial applications.

This growing portfolio of completed orders reflects our proven capability in custom diaphragm seal manufacturing, fast response to customer requirements, and consistent delivery quality for global process industries.

Tell us your process conditions, pressure range, temperature, and flange requirements. Our engineers will review your application and provide a technically matched diaphragm seal solution.