OEM Pressure Transmitter

SIY Electric specializes in OEM pressure transmitter manufacturing, offering flexible design, private labeling, and scalable production for industrial partners.

what is OEM pressure transmitter

An OEM pressure transmitter is a customized pressure measurement solution designed for brand owners and equipment manufacturers who require high-reliability pressure monitoring instruments but do not have production capabilities or prefer not to invest in manufacturing resources.

As a professional pressure transmitter manufacturer, SIY provides comprehensive services for the design, machining, assembly, testing, and strict quality control of pressure and differential pressure transmitters. We also label the final products with your brand and logo.

Whether you require specific output signals, pressure ranges, process connections, housing structures, labeling, packaging, or certification support, we offer flexible customization based on your requirements to meet the needs of various industrial applications.

Through this cooperation model, you can expand your product portfolio more efficiently, reduce development and manufacturing costs, and quickly introduce your own branded pressure transmitter products into fields such as industrial automation, energy monitoring, and smart HVAC systems.

types of OEM pressure transmitter in SIY

Any type of pressure or differential pressure transmitter/sensor you need.

in line pressure transmitter

The in-line pressure transmitter (also known as a smart pressure transmitter or threaded pressure transmitter) is mainly used to measure gauge pressure, vacuum pressure, and absolute pressure of gases, liquids, and steam. It converts the measured values into a standard 4–20 mA DC output signal.

The product adopts an advanced single-crystal silicon resonant sensing element, which detects changes in resonant frequency to measure pressure, offering high accuracy, excellent long-term stability, and low temperature drift.

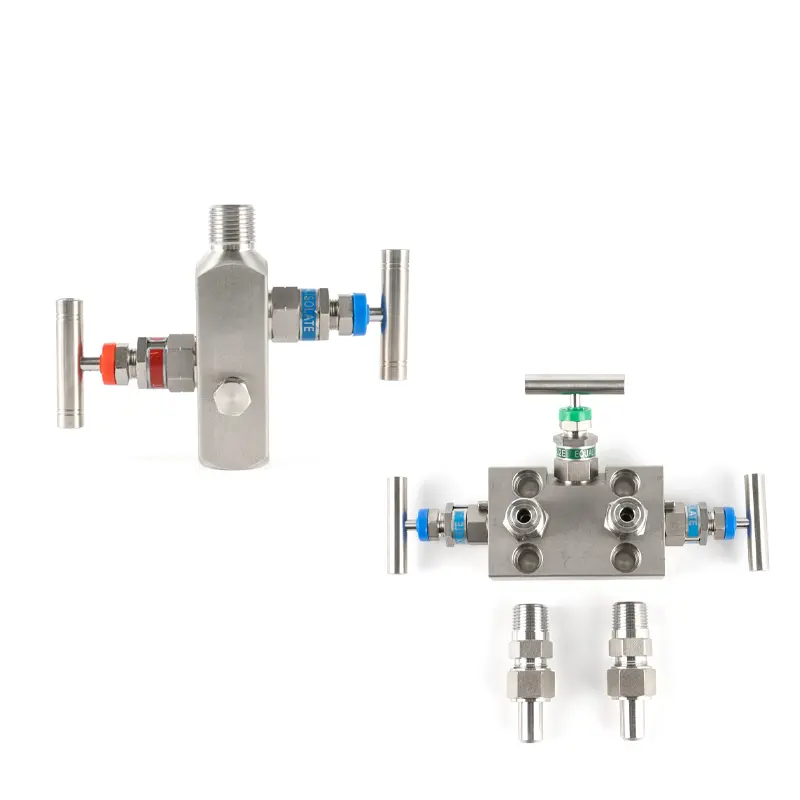

The transmitter features the traditional 3051-style design, with an appearance and installation method similar to the Rosemount 3051TG. It can be directly mounted on equipment or pipelines via the bottom threaded connection. It is commonly used in conjunction with accessories such as two-valve manifolds, shut-off valves, and heat dissipators to meet various installation and maintenance requirements.

differential pressure transmitter

The differential pressure transmitter is mainly used to measure the differential pressure, level, and flow of liquids, gases, and steam, and to convert the measured values into a standard 4–20 mA DC output signal. It is widely used in process control applications in the petroleum, chemical, power, metallurgy, and environmental protection industries.

The product adopts an advanced single-crystal silicon resonant sensing element, which detects the pressure difference between the two sides by monitoring changes in resonant frequency. It features high measurement accuracy, excellent long-term stability, low temperature drift, and strong overload resistance, and is particularly suitable for low differential pressure measurement.

Its structure, appearance, and mounting method are similar to the Rosemount 3051CD. It is typically installed on process pipelines or vessels using a mounting bracket, and can be equipped with accessories such as three-valve manifolds, shut-off valves, and impulse tubing to meet the installation and maintenance requirements of various differential pressure measurement applications.

2088 pressure transmitter

The 2088 pressure transmitter, also known as a diffused silicon pressure transducer, is mainly used to measure gauge pressure or absolute pressure of liquids, gases, and steam, and converts the measured pressure into a standard 4–20 mA DC signal. With its low cost and high cost-performance ratio, it is widely used in industries such as petroleum, chemical, electric power, and water supply and drainage.

At its core, the product adopts a high-performance diffused silicon pressure sensing chip, featuring fast response, high measurement accuracy, and excellent long-term stability, making it suitable for continuous pressure measurement in various industrial applications.

The pressure sensor adopts the classic 2088 housing design, similar to the Rosemount 2088, with a compact size and robust construction. It offers a variety of process connections and electrical interface options, and can be equipped with a local digital display. By selecting different sealing materials and structural configurations, it can meet the pressure measurement requirements of general media, mildly corrosive media, and certain high-temperature applications.

compact pressure transmitter

The Compact pressure transmitter, also known as a Pressure Sensor or Micro Pressure Transmitter, is commonly used for pressure monitoring in machinery, pipeline systems, and refrigeration/air-compression units. It is capable of measuring gauge pressure or absolute pressure of gases, liquids, and steam, and provides a standard 4–20 mA output signal.

The sensor employs a highly reliable diffused-silicon sensing element combined with an integrated signal conditioning circuit. Through temperature compensation and zero-point correction, it ensures linear signal conversion and stable pressure output, featuring strong anti-interference capability, good environmental adaptability, and excellent long-term stability.

The pressure transducer features a fully stainless-steel construction and is equipped with a DIN Hirschmann electrical connector for simple and reliable installation. Various pressure ranges and process connection options are available to match different media and operating conditions, making it suitable for oil, water, air, refrigerants, and other common industrial fluids. As a professional pressure sensor manufacturer, SIY supplies a large number of pressure sensors annually to customers worldwide in industrial equipment and process control applications.

sanitary pressure transmitter

The Sanitary Pressure Transmitter (also known as a Hygienic Pressure Transmitter) is designed for pressure monitoring in the food processing, dairy production, beverage, pharmaceutical, and bioprocess industries. The transmitter features a hygienic diaphragm-sealed structure capable of measuring gauge or absolute pressure in liquids, slurries, and media containing solids, with output options including 4–20 mA or digital signals. Its Tri-Clamp sanitary connection enables quick installation and meets CIP/SIP cleaning and aseptic process requirements, making it suitable for sanitary pipelines and equipment.

To accommodate different installation spaces and system configurations, the hygienic pressure transmitter is available in multiple structural versions, including the 2088-type, 3051 industrial type, and compact micro sanitary transmitter designs. Various pressure ranges, diaphragm materials, and process connection specifications are supported. It is suitable for water, milk, syrup, beer, fermentation media, and a wide range of pharmaceutical liquids, providing a versatile pressure measurement solution for hygienic process control environments.

submersible level transmitter

The Submersible Pressure Transmitter, also known as a Hydrostatic Pressure Level Transmitter, is designed for liquid level and pressure measurement in various media and is widely used in water treatment, environmental engineering, industrial storage tanks, and similar applications. By immersing the probe directly into the liquid, the transmitter measures hydrostatic pressure and provides a standard 4–20 mA or digital output signal.

The product is available in a 2088 housing with an optional local display, along with multiple pressure ranges and cable length configurations. The stainless-steel probe is equipped with a waterproof cable and a vented tube design for atmospheric reference, ensuring stable and reliable performance during long-term submersion. This hydrostatic measurement method makes the transmitter suitable for clean water, wastewater, groundwater, lakes, chemical solutions, and tank level monitoring, offering a versatile and dependable solution for liquid level applications.

diaphragm seal pressure transmitter

The Diaphragm Seal Pressure Transmitter is designed for pressure and level measurement in high-temperature, high-viscosity, and corrosive media. Using a flanged diaphragm seal to isolate the sensor from the process medium, it is ideal for chemical processing, petrochemical, pharmaceutical, and food industry applications.

The flange-mounted pressure transmitter equips a high-stability sensing element with selectable diaphragm materials and standard flange options such as DN50 and DN80. Its fill-fluid transmission system, combined with temperature compensation, ensures accurate, low-drift performance for demanding chemical pressure measurement tasks.

Engineered for harsh environments, this corrosive media pressure transmitter provides a reliable solution for applications requiring stable diaphragm-seal pressure measurement and long-term process control.

capillary pressure transmitter

The Capillary Diaphragm Seal Pressure Transmitter differs from a single-flange direct-mount transmitter by using a capillary tube to separate the diaphragm seal from the transmitter body. This capillary structure effectively reduces the impact of process temperature on the transmitter, improving its high-temperature resistance and installation flexibility, while also allowing for more convenient on-site observation.

The remote mounted pressure transmitter adopts a single-crystal silicon sensing element and offers various flange sizes and diaphragm materials. Process pressure is transmitted through the fill fluid inside the capillary tube to the measuring cell. With integrated temperature compensation and a precise signal conditioning circuit, the transmitter maintains excellent measurement accuracy and long-term stability even under high-temperature fluctuations and challenging process conditions.

diaphragm seal differential pressure transmitter

The Diaphragm Seal Differential Pressure Transmitter is designed for differential pressure and level measurement in applications involving highly corrosive, high-viscosity, solid-containing, or crystallizing media. By isolating the process medium with a diaphragm seal, the transmitter prevents the differential pressure sensor from corrosion, clogging, or contamination. It is widely used in critical process control across the chemical, petrochemical, pharmaceutical, food, pulp & paper, and energy industries.

The transmitter utilizes a high-performance single-crystal silicon differential pressure sensor, with the process pressure on the high-pressure (H) side transmitted to the measuring cell through a fill fluid. With built-in temperature compensation and linear correction, it provides excellent measurement accuracy, long-term stability, and strong anti-interference performance, making it suitable for level measurement, differential pressure flow measurement, and other demanding applications.

capillary differential pressure transmitter

The Capillary Diaphragm Seal Differential Pressure Transmitter is mainly used for single-side differential pressure, level, and low differential pressure measurement applications. The capillary length can be customized according to site installation requirements, making the transmitter especially suitable for high-temperature media and high-vibration operating conditions. It is well-suited for remote measurement applications and provides an ideal solution for differential pressure and level measurement in complex and demanding process environments.

The transmitter adopts a single-crystal silicon resonant differential pressure sensor. The high-pressure side is isolated from the process medium by a flanged diaphragm seal, and the pressure signal is transmitted to the sensor through a filled capillary system. The low-pressure side is directly vented to the atmosphere, enabling differential pressure or level measurement. This structure effectively prevents corrosion, clogging, or contamination of the sensor by the process medium, ensuring stable and reliable long-term operation.

Dual Flange Differential Pressure Transmitter

The Dual Flange Differential Pressure Transmitter is designed for differential pressure and level measurement in sealed and pressurized equipment. Both the high-pressure (H) side and low-pressure (L) side are connected via flanged diaphragm seals, making it particularly suitable for level and differential pressure measurement in closed vessels, reactors, columns, and other pressurized process equipment.

The dual flange level transmitter adopts a high-performance single-crystal silicon differential pressure sensor, with the pressure signals transmitted to the measuring chamber through a filled capillary system. This fully isolated structure effectively protects the sensor from corrosive, high-viscosity, solid-containing, or crystallizing media. The dual flange differential pressure transmitter features high measurement accuracy, excellent long-term stability, and low temperature drift, ensuring stable and reliable performance under harsh process conditions.

Pressure Transmitter

From

OEM Instrument Manufacturer

Functions of Pressure Transmitter

- Pressure Measurement

- Signal Conversion

- Differential Pressure and Level Measurement

- Process Control

- Alarm and Protection

- Remote Monitoring

- Calibration and Compensation

- Data Acquisition and Recording

Benefits Of SIY

- Pressure Transmitter manufacturer and supplier in China

- The professional service team, timely and effective

- 10+ years of manufacturing experience

- Complete manufacturing process to provide safe products

- ISO & CE Certificate

- Support OEM customization with customer branding

- Lower cost

- Fast Delivery

Pressure Transmitter VS Pressure Sensor

Terminology Clarification

A pressure sensor is essentially a core component of a pressure transmitter. It is used to sense pressure and convert the pressure signal into a weak electrical signal. A pressure transmitter amplifies, compensates for, and linearizes the electrical signal from the sensor, then outputs it as a standard 4–20 mA signal.

However, in daily use and marketing practice, it is necessary to distinguish between different types of pressure transmitters. The term pressure sensor is commonly used to refer to compact pressure transmitters or 2088-style diffused silicon pressure transmitters, while pressure transmitter is more often used to describe 3051 smart pressure transmitters or 3051 smart differential pressure transmitters.

Pressure Transmitter

advantages

Standard 4–20 mA output, suitable for long-distance signal transmission

High measurement accuracy with better reliability and long-term stability

Strong resistance to electromagnetic interference, ideal for industrial environments

Better environmental adaptability, capable of stable operation under harsh conditions

High market acceptance, widely used in DCS and PLC process control systems

disadvantages

Higher overall cost

More complex installation and maintenance requirements

- The manufacturing process is relatively complex, resulting in a longer lead time.

Pressure Sensor

advantages

Compact structure and small size, easy to install and integrate

Lower cost, suitable for cost-sensitive applications

Faster delivery, with simpler manufacturing processes and shorter production cycles

disadvantages

Lower measurement accuracy, typically around ±0.5% FS

Weak anti-interference capability, easily affected by external electromagnetic signals (such as walkie-talkies)

Short signal transmission distance, not suitable for long-distance applications